Polymer Synthesis 2

Synthesis of polymeric nanoparticles via CO2-induced miniemulsion polymerization

Investigators:

Prof Per Zetterlund

A/ Prof Frank Lucien

The aim of this research stream is to develop energy-efficient, environmentally friendly and versatile methods for synthesis of polymer and polymeric nanoparticles via miniemulsion polymerization. Polymeric nanoparticles find a wide range of applications in for example materials science and nanomedicine. Miniemulsions (also referred to as nanoemulsions) are kinetically stable but thermodynamically unstable sub-micron sized (typically in the diameter range 50 – 500 nm) dispersions of oil (e.g. vinyl monomer) in water. Miniemulsion polymerization is distinct from the traditional emulsion polymerization process in that polymer particles are generated from monomer droplets, as opposed to nucleation in the continuous phase via micellar and/or homogeneous nucleation. This mechanistic aspect is the reason for the attractiveness of miniemulsion polymerization for nanoparticle synthesis. Since miniemulsion polymerization possesses the inherent advantage that ideally each monomer droplet is transformed into a polymer particle and diffusion across the aqueous phase is not required, the process conveniently lends itself to synthesis of hybrid polymer particles, hollow polymer particles, as well as implementation of controlled/living radical polymerization (CLRP). Since miniemulsions are thermodynamically unstable, energy input is required for their formation, traditionally in the form of high energy homogenization via ultrasonication or high pressure homogenization. This requirement remains an impediment to industrial implementation of miniemulsion polymerization, and it is therefore of interest to develop alternative low energy methods to generate miniemulsions for polymerization, as well as to device convenient methods to tune the droplet/particle size.

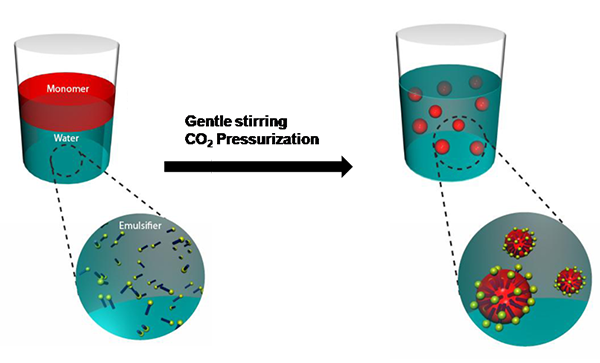

Figure 1. Schematic illustration of CO2-induced generation of a miniemulsion.

The cornerstone of the project is the generation of miniemulsions by use of a novel method making use of compressed CO2. It entails the addition of CO2 to a relatively low pressure of approximately 5 MPa to a stirred mixture of oil (e.g. vinyl monomer), water and surfactant, leading to formation of a miniemulsion without application of a high energy shear device. Under appropriate conditions, a transparent emulsion is formed, i.e. droplets with radius < 30 nm, and the particle size can be conveniently controlled by the CO2 pressure. The presence of the compressed gas is crucial in the formation and stability of the oil droplets. The process holds promise of great versatility, and has been successfully utilized with anionic, cationic and nonionic surfactants.

Figure 2. Effect of CO2 pressure on aqueous emulsions of styrene monomer. The emulsion turns transparent at the transparent pressure (PT) due to formation of submicron-sized droplets

References

- Size-Tunable Nanoparticle Synthesis by RAFT Polymerization in CO2-Induced Miniemulsions, S. Cheng, S. R. S. Ting, F. P. Lucien, P. B. Zetterlund, Macromolecules 2012, 45, 1803−1810.

- Nanoemulsions Induced by Compressed Gases, Zhang, J.; Han, B.; Zhang, C.; Li, W.; Feng, X. Angew. Chem., Int. Ed. 2008, 47, 3012−3015.